Measuring & Testing Technology

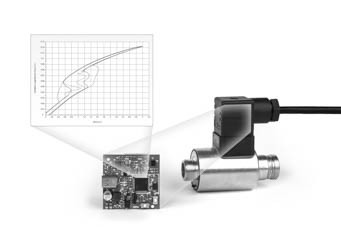

MagHyst® automation

MagHyst® automation is a testing system adapted to defined customer specific test tasks for the 100% quality control of all ferromagnetic components along the entire value chain. It is designed for usage within production plants and is applicable for in-line tests as well as end-of-line tests.

By means of the magnetic measurement it is possible to detect electric, magnetic and mechanic assembly faults of the actuator sensorless and non-destructive, even in the semi-assembled state.

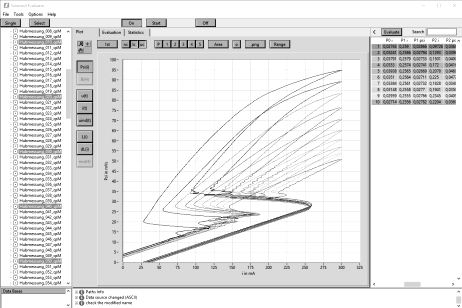

The automatic evaluation of the measured data only takes milliseconds or seconds, the results are visualised user-friendly and stored within a database for further analysis and statistics. Various field-bus-systems are available for connection to the PLC.

The measured characteristics deliver a variety of information of the actuator:

- Switching currents

- Air gap

- Stick Slip effects

- Armature movement

- Forces within the actuator such as friction and springs

- Influences of the production process

Technical specification

| Maximalum current | 10 A |

| Maximum voltage | 24V |

| Dimensions: | 19“ 3RU 30cm |

| Weight: | approx. 10kg |

| Cycle times (depending on measurement parameters) | starting at 1s |

| Min. Samplerate: | 100kS/s (Δt = 10µs) @ 16 bit |

| Delivery content: | measurement device, PC, peripherals, software (Windows) |

| Interfaces: | profibus, profinet, CC-Link, Ask for more interfaces |