Measuring & Testing Technology

MagHyst® multiplexer

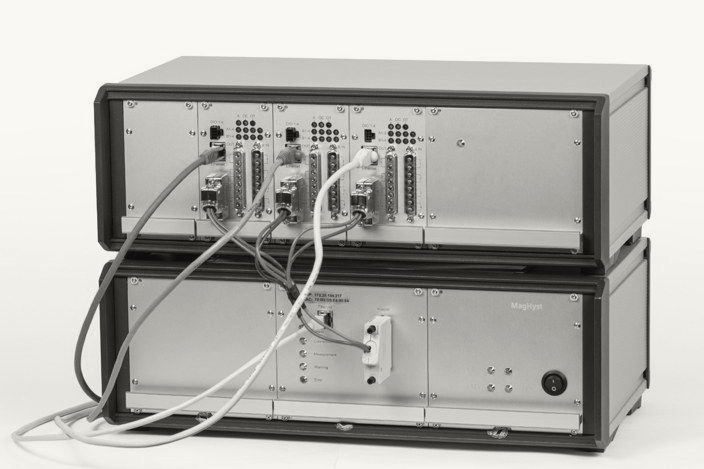

MagHyst® Multiplexer is a key component for significantly expanding the functionality of our MagHyst®Platform.

In combination with MagHyst® automation, it enables fully automated sequential measurement of multiple test objects – without manual switching or rewiring.

This makes the testing process much more efficient and reliable, especially during long-term endurance tests. In this way, electromagnets can be monitored regularly and with high precision over extended periods.

This allows even the smallest changes to be detected at an early stage, potential error sources to be identified with certainty, and a deeper understanding of the causes of deviations to be gained.

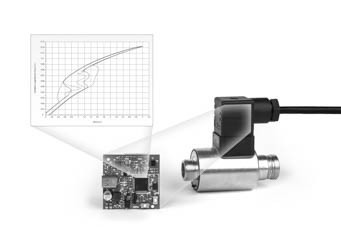

To achieve this, MagHyst® multiplexer temporarily disconnects each test object from the control unit of the test bench in order to enable a highly precise MagHyst® measurement. The object is then tested according to the predefined measurement procedure.

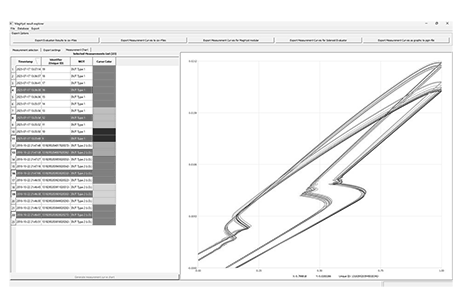

Once the measurement is complete, the multiplexer reconnects the object to its external control and automatically switches to the next actuator. This cycle continues in any order and duration and can be freely configured using the associated software. Through the integrated evaluation algorithm, all measurement results are recorded seamlessly, ensuring that both short-term changes and long-term trends are documented precisely and traceably.

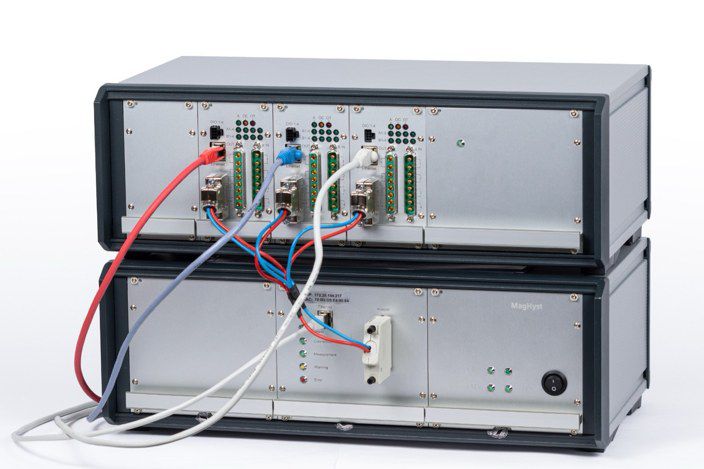

Several multiplexers can be combined with a MagHyst® automation to test up to 20 actuators with a single device. Thanks to its modular architecture, MagHyst® multiplexer can also be easily integrated into existing test benches, allowing current test environments to be expanded with minimal effort.

By enabling multiple test objects to share the same measurement channel, MagHyst® multiplexer reduces the need for additional hardware and minimizes setup time. Testing becomes faster, more consistent, and less error-prone, since no manual reconnection is required. At the same time, the scalability and flexibility of the system ensure that even complex test scenarios can be handled with ease.

The use of the multiplexer makes the MagHyst® Platform even more flexible and efficient. It transforms the measurement process from a sequence of manual steps into an optimized, automated routine that processes many objects within a single workflow.

For you as a user, this means significant time savings, reduced complexity, and the assurance that your measurement results are always fully documented, continuously monitored, and clearly evaluated.

Technical specification

| Maximum current | 10 A |

| Maximum voltage | 24V |

| Dimensions (L x W x H) | 470 mm x 270 mm x 160 mm |

| Weight | ≈ 10 kg |

| Number of actuators | Max. 20 |

| Interfaces | Ethernet, measurement objects (D-Sub 8W8), external actuator control (D-Sub 8W8), MagHyst®(7W2) |